Water jet propulsion systems are essential for high-speed vessels such as ferries, military boats, and luxury yachts. Compared to traditional propellers, they provide advantages like better maneuverability, reduced risk of damage in shallow waters, and improved safety. However, to achieve optimal performance and longevity, it is crucial to understand and enhance the efficiency and durability of the system’s core components. This article discusses the most critical parts of a water jet propulsion pump and explores strategies to minimize energy loss, reduce mechanical wear, and enhance operational reliability.

Key Components and Optimization Strategies

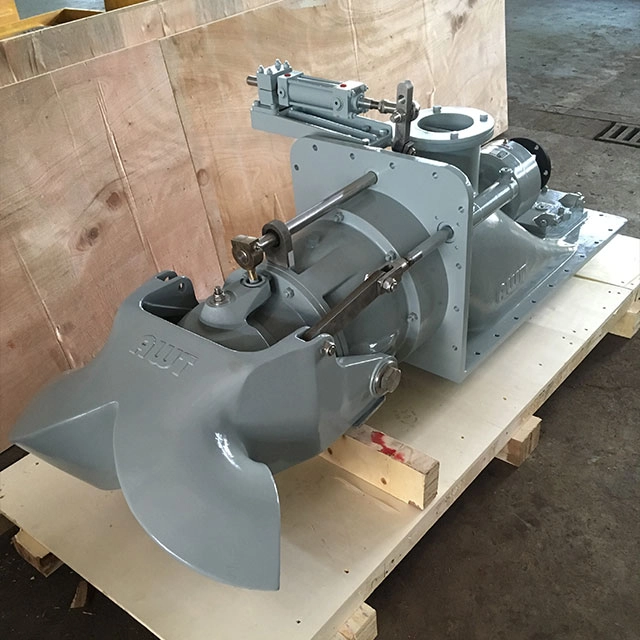

The impeller generates thrust by accelerating water flow through the pump. Its design significantly impacts propulsion efficiency and fuel consumption.

Challenges

- Cavitation and turbulence cause energy loss.

- Wear and corrosion reduce performance over time.

Optimization Strategies

- Optimize intake design to ensure smooth and stable water flow.

- Use anti-cavitation impellers with improved blade profiles.

- Maintain proper water levels to prevent excessive suction pressure.

- Utilize real-time pressure monitoring to detect cavitation early and adjust operational settings accordingly.

The nozzle directs high-velocity water out of the system, creating thrust and allowing directional control.

Challenges

- Poorly designed nozzles cause energy loss and inefficient propulsion.

- Excessive wear from high-speed water flow reduces lifespan.

Optimization Strategies

- Utilize variable – pitch nozzles to adjust flow angles dynamically based on operating conditions.

- Use ceramic coatings or hardened alloys to resist erosion from continuous high – velocity water exposure.

- Design nozzles with adjustable geometries to enhance maneuverability and efficiency at different speeds.

The intake duct directs water into the pump while minimizing turbulence and pressure loss.

Challenges

- Poorly designed intakes can cause air entrapment, reducing propulsion efficiency.

- Foreign objects and marine debris can clog the intake, affecting performance.

Optimization Strategies

- Implement streamlined intake shapes to maintain smooth, stable water flow and reduce turbulence.

- Use protective grates and self – cleaning filtration systems to prevent debris from entering the system.

- Optimize intake placement and angle to balance water flow and minimize resistance.

Bearings and the propulsion shaft transmit power from the engine to the impeller while minimizing energy loss due to friction.

Challenges

- Friction leads to heat buildup and mechanical wear.

- Water exposure accelerates corrosion and degradation.

Optimization Strategies

- Use ceramic or hybrid bearings with self-lubricating properties to reduce friction and heat generation.

- Implement sealed bearing housings to prevent water ingress and extend component lifespan.

- Utilize active lubrication systems to enhance cooling and reduce wear.

Seals protect internal components from water intrusion, preventing damage and reducing maintenance needs.

Challenges

- Poor – quality seals wear out quickly, leading to leakage and system failure.

- High operating pressures can degrade seal integrity.

Optimization Strategies

- Use high – performance elastomeric or composite seals designed for high – speed marine applications.

- Implement pressure – compensating seals to maintain effectiveness under varying loads and conditions.

- Regularly inspect and replace seals to prevent failures and prolong system durability.

Enhancing Durability and Longevity

Beyond optimizing individual components, adopting the following strategies can further extend the lifespan of water jet propulsion pumps:

- Regular Maintenance & Inspection – Periodic checks of key components help detect early signs of wear and prevent costly breakdowns.

- Real-Time Monitoring Systems – Using IoT sensors and AI-based diagnostics can track system performance and predict failures before they occur.

- Advanced Coatings & Materials – Anti-corrosion coatings, composite materials, and reinforced alloys significantly improve component durability.

- Optimized Operating Procedures – Ensuring correct speed, pressure, and maintenance intervals minimizes excessive stress on propulsion components.

Water jet propulsion pumps rely on well-designed impellers, nozzles, intake ducts, bearings, and seals to achieve high efficiency and durability. By implementing hydrodynamic optimizations, advanced materials, and real-time monitoring, operators can enhance propulsion performance, reduce mechanical wear, and extend the system’s lifespan. As maritime technology advances, integrating smart control systems and AI-driven maintenance solutions will further revolutionize water jet propulsion, ensuring its continued evolution as a high-performance propulsion method.