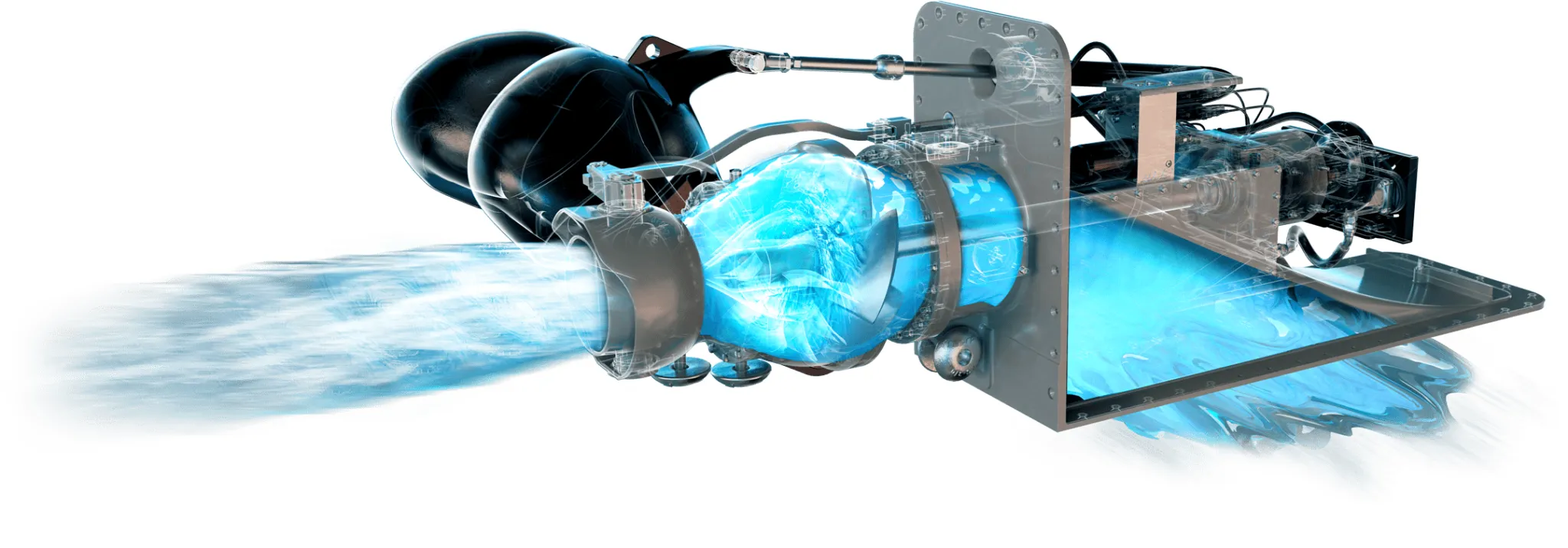

Water jet propulsion has become a preferred choice for high-speed vessels, ferries, and military boats due to its advantages over traditional propeller systems. These benefits include better maneuverability, reduced draft requirements, and improved safety in shallow waters. However, the system’s reliance on high-velocity water flow makes it vulnerable to specific operational failures that can reduce efficiency and increase maintenance efforts. Identifying and mitigating these common issues is crucial for maintaining optimal performance and reliability.

Common Failures and Solutions

Issue

- Cavitation occurs when pressure drops below the vaporization point of water, forming bubbles that collapse and cause damage to pump components.

- It leads to efficiency loss, noise, vibration, and impeller erosion.

Solutions

- Optimize intake design to ensure smooth and stable water flow.

- Use anti-cavitation impellers with improved blade profiles.

- Maintain proper water levels to prevent excessive suction pressure.

- Utilize real-time pressure monitoring to detect cavitation early and adjust operational settings accordingly.

Issue

- Water jet propulsion systems are susceptible to debris intake, such as seaweed, plastic, and small marine organisms, leading to blockages.

- Large foreign objects can damage impellers and nozzles.

Solutions

- Install high-efficiency intake grates and filters to prevent large debris from entering the system.

- Regularly clean the water intake and internal channels to avoid accumulation.

- Use self-cleaning or automatic filtration systems to remove small particles efficiently.

- Educate operators on avoiding operations in areas with heavy floating debris.

Issue

- Poorly designed water flow paths can result in energy loss, reducing thrust and increasing fuel consumption.

- Misalignment of the pump and nozzle can decrease propulsion effectiveness.

Solutions

- Utilize Computational Fluid Dynamics (CFD) simulations to refine the pump’s hydrodynamic design.

- Regularly inspect and align nozzle angles to optimize thrust output.

- Ensure smooth internal surfaces to minimize turbulence and water resistance.

- Upgrade to variable – pitch nozzles that adjust based on operating conditions.

Issue

- Excessive pump operation at high loads can cause heat buildup, affecting efficiency and damaging seals and bearings.

- Poor cooling system performance can lead to engine and hydraulic overheating.

Solutions

- Implement enhanced cooling systems with better heat dissipation materials.

- Optimize lubrication mechanisms to reduce friction – induced heat.

- Use temperature sensors to monitor overheating risks and trigger alarms before critical failure.

- Conduct routine inspections of bearings and seals to prevent thermal degradation.

Issue

- Continuous exposure to saltwater and high – speed water flow leads to impeller, shaft, and seal degradation over time.

- Corrosion reduces the lifespan of key components.

Solutions

- Use marine – grade stainless steel, titanium, or composite materials for corrosion – resistant components.

- Apply protective coatings to impellers and casings to reduce wear and oxidation.

- Implement predictive maintenance with real – time monitoring to detect early signs of mechanical wear.

- Periodically replace worn – out components to maintain performance.

Preventive Maintenance Strategies

To ensure long-term reliability and efficiency, adopting a proactive maintenance approach is essential. Recommended practices include:

- Routine inspections: Check impellers, nozzles, bearings, and seals for wear and damage.

- Automated monitoring systems: Utilize IoT-based sensors for real-time diagnostics.

- Regular cleaning and flushing: Prevent debris accumulation and biofouling.

- Proper alignment and calibration: Adjust nozzles and impellers for maximum efficiency.

- Scheduled part replacements: Avoid unexpected failures by following manufacturer guidelines.

Water jet propulsion pumps offer numerous advantages for high-speed marine applications but are prone to common failures such as cavitation, clogging, energy loss, overheating, and mechanical wear. By implementing optimized design strategies, smart monitoring systems, and preventive maintenance, vessel operators can significantly enhance propulsion performance and reduce operational costs. As technology advances, integrating AI-driven diagnostics and advanced materials will further improve the efficiency and reliability of water jet propulsion systems.